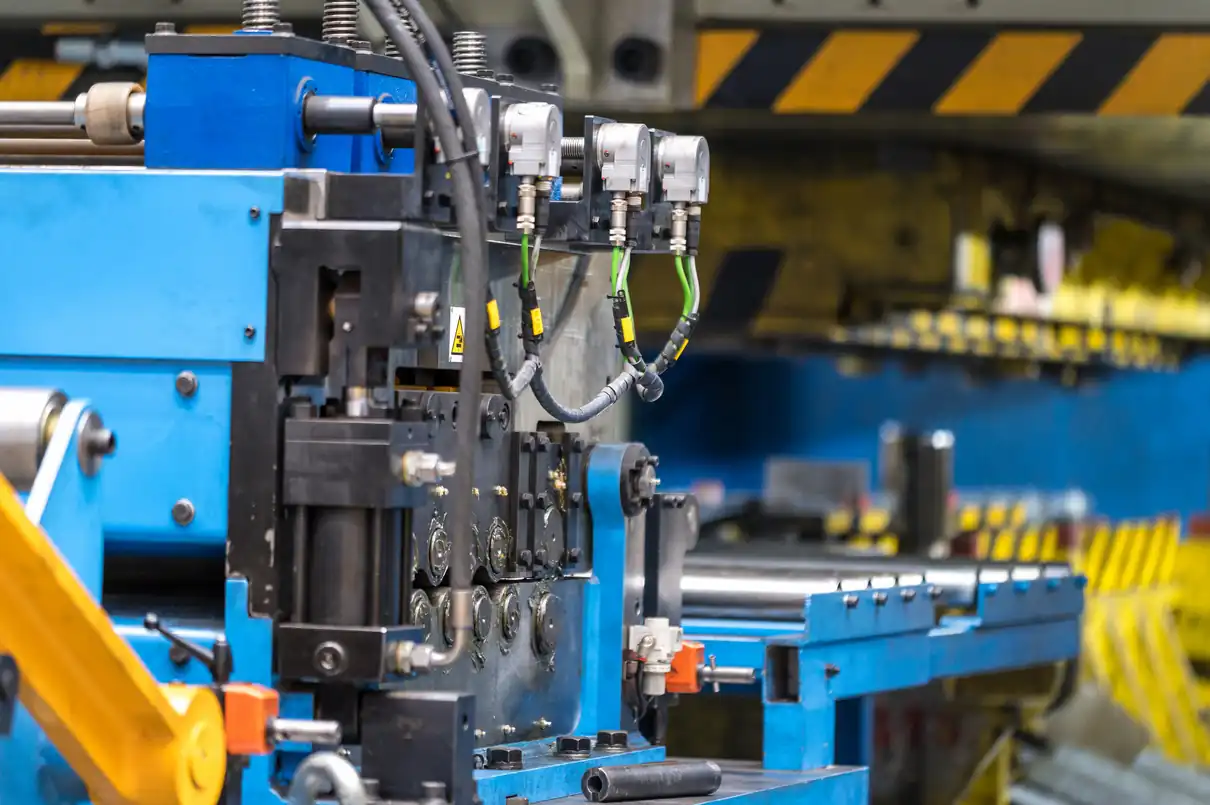

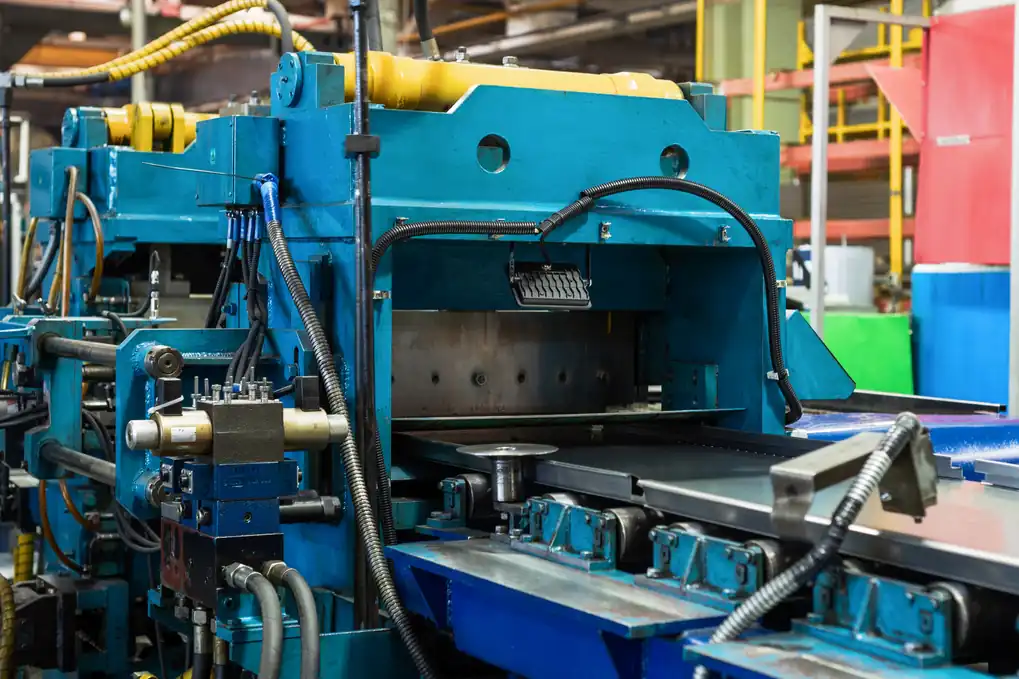

equipped with update to date

facilities

make sure the high quality of the products

DUNTEK's Modern

Workshop

High Standard Products Producing From Here

Metal & Plastic Customization Manufacture Service

Custom manufacturing and processing of metal and plastics materials are the main industries of DUNTEK that provides a full range of services adapted to the specific field of industry. Our business cuts across the various industries offering accurate and custom engineered components and finished products out of high quality stainless steel, aluminum, titanium and value added plastics, and other alloy products. Combined with DUNTEK's CNC machining and 3D printing business departments, DUNTEK can provide customers with optimal solutions for a wide range of needs.

DUNTEk's Solution for Customized Products / Components

With the latest technology of CNC machining, stamping, casting and 3D (three-dimensional) printing, our plants are capable of meeting demanding design requirements in large volume production. Regardless of whether the elements are made of metal or flexible plastics, DUNTEK takes care of a precise and high-quality manufacturing of every product.

This commitment to customization also entails that DUNTEK will be involved in client consults to ensure that solutions being offered meet clients’ needs to the letter. Throughout the overall design to the actual completion of the products, we assist our clients in every step of the way to guarantee the outcome that fullfills their expectation in terms of design and quality. What it means is that through DUNTEK, clients can be assured their products are manufactured using sophisticated technology that not only produces functional and long lasting products but those that meet very specific requirements of their respective companies .

What Can DUNTEK Offer?

Turn-key Solution for Customized Products

DUNTEK offer clients with high-precision products processing and full-cycle services with composite processing method. Client's satisfaction is DUNTEK's ultimate pursuit. What can DUNTEK meet?

- High-Quality Precision

- Advanced Technological

- Rapid Repsonse & Delivery

- Comprehensive Services

- Customization and Flexibility

- Expertise and Technical Support

- Quality Assurance and Certification

- Cost-Effectiveness

Professional

Customization

for Your Unique Needs

DUNTEK offers clients dynamic and personalized solutions for metal and plastic products processing based on the unique individual demand.

Why Choose Us?

Advanced Technology

DUNTEK uses state of the art processing equipment with advanced technology that allows us to meet the most complicated tasks in terms of individual and personalization. We can handle different needs for personal or team.

Flexibility and Scalability

We are fully capable to undertaking small and simple customized products processing projects to complex and bulky projects as well. Flexibility of the production systems means that the firm can easily meet new needs from customers or adapt to any new trends in the market.

Quality Assurance

DUNTEK always take the quality as the first. Meticulous quality control procedures are observed, starting with the inspection of each product by the use of more sophisticated inspection tools and procedures. Our factory is ISO 9001 compliant.

Customer-Centric Approach

At DUNTEK, we are always customer-centered and take customer satisfaction as our relentless pursuit. We firmly believe that we gain after our customers gain, which is the cornerstone of long-term cooperation.

Expert Team

DUNTEK's principles have been into engineering and machinists' knowledge and experience. When working on projects, clients’ needs are often fully considered in order to provide exactly whatever they need and whenever they need it.

Shipping Solutions

DUNTEK offers personalized shipping solutions for international customers. There is no need to worry about any transportation issues, and DUNTEK's diverse range of partner logistics providers can meet your unique needs.

Our Story

Company Foundation

Based on a keen grasp and accurate exploration of the market, and with nearly 10 years of experience working in the customization field, DUNTEK was established in 2015. As the original intention of our company’s creation is to provide the ultimate turnkey CNC machining service for customized clients, including but not limited to metal materials, plastics, new materials, etc., from idea creation to final product.

Whether it is an industrial product component or a final retail product, DUNTEK is able to consistently provide our customers with high quality and standard products through the years of experience in the market and supply chain integration of the founding team of DUNTEK.

Expanding CNC Machining Workshop

Two years after the establishment of the company, due to the growing maturity of the company’s business, in order to fully meet the various refined needs of customers, DUNTEK expanded the CNC machining workshop and introduced advanced 5-axis CNC machine tools, which are able to meet the needs of customers in different industries, including, but not limited to, the automotive industry, the aerospace industry, precision mold manufacturing, medical equipment, industrial components, consumer goods, robotics parts, etc. and many more.

By upgrading the equipment and workshop, DUNTEK is able to provide customers with better quality products and services. Meanwhile, over the years, DUNTEK has maintained its focus and enthusiasm on the latest technology, constantly exploring cutting-edge technologies and applying them to our in-house testing products – until they are mature enough to be utilized and offered to our customers.

Entering 3D Printing Market

To more effectively address the requirements for precise CNC machining customization by clients, DUNTEK has been expanding to the 3D printing activity since 2019. By integrating DUNTEK’s engineering experts with the help of technology, we have made it possible for our clients to avail the best solutions with increased precision. New equipment has been brought into DUNTEK’s workshop, with the industrial 3D printer packages that have the ability of working with metals and other composite products backed by common consumer 3D products which are familiar to the market.

This has allowed the creation of complicated designs and shape geometries of vectors that are not achievable in traditional manufacturing. Thus, the scope of our 3D printing division targets all – from industrial components or prototypes, to consumer products. Adding 3D printing into the list of services, helps us to offer our clients even more innovative, precise, and high-quality solutions for contemporary demands of the industry.

Infinite Possibilities for the Future

As we further extend our activities into the 3D printing industries and advanced CNC (Computer Numerical Control) manufacturing solutions which we are already offering, the focus lies on the development of innovative solutions for an enhanced quality to be reached. For the further development in the future, DUNTEK is to enhance the relations with clients, offering our clients the individual instruments which will satisfy their requirements and overcoming difficulties. Realizing that research and development is crucial in the constantly growing and advancing industry, it is our goal to provide ever-increasing satisfaction regarding the offered products and services. At DUNTEK, we offer value, encourage innovations, and contribute to development of our clients, making a better future by working together.

Parts of DUNTEK's Happy Clients...

"It is worth stating that the quality of the components that we purchased from DUNTEK is first-rate. Each segment was made to explicit high standards, as was compliance with the quality that we consider ideal. Great job!"

“I want to emphasize the professionalism and expertise of DUNTEK’s team which was always helpful and gave necessary advice throughout our cooperation, we have great communication all the time. ”

"DUNTEK does wonderful work with the equipment they have and the accuracy of the CNC machining is impeccable! They were able to meet the level of detail put into our parts combined with very important tolerance limits for our application that require high-performance aerospace components."

"We had a complicated project which as such called for unique solutions – DUNTEK went above my expectation in this area: the company has the ability to respond to our peculiar needs and, therefore, what we received was perfect."

“DUNTEK pays the utmost attention to detail: this is exactly what our products require! DUNTEK's team of experts is always at my disposal to ensure that the products are developed and put into production on time!”

Explore All Business of DUNTEK

Explore DUNTEK's diversified high-end manufacturing business to precisely match your needs and provide you with the best solutions and high-precision, high-quality products.