Aluminum Rapid Prototyping Service refers to the rapid creation of prototype parts and models using aluminum as the primary material. For industries where the product cannot be made from heavy, strong, and not corrosion material, such as aerospace, automotive and electronics, aluminum prototyping has a significant performance in the earlier stages of product development. Designed for designers and engineers, this service allows functionality, design, and performance to be tested against full scale design and production before investing. Aluminum is a material well suited for rapid prototyping, where speed and accuracy is important in an iterative design process that requires value in quick feedback and adjustment.

What is Aluminum Rapid Prototyping Service?

Aluminum Rapid Prototyping Service refers to the rapid creation of prototype parts and models using aluminum as the primary material. For industries where the product cannot be made from heavy, strong, and not corrosion material, such as aerospace, automotive and electronics, aluminum prototyping has a significant performance in the earlier stages of product development.

Designed for designers and engineers, this service allows functionality, design, and performance to be tested against full scale design and production before investing. Aluminum is a material well suited for rapid prototyping, where speed and accuracy is significant in an iterative design process that requires value in quick feedback and adjustment.

How to Make Aluminum Rapid Prototyping: The Process?

The aluminum rapid prototyping process involves several detailed steps:

Design & 3D modeling: The part is then designed in 3D CAD software, which initiates the prototyping process. The blueprint for the prototype, this digital model has precise measurements, structural details and all in between.

Material Selection: There are unique properties for aluminum – it is lightweight, particularly strong, and naturally corrosion resistant. For some projects, 6061, 7075 and other alloys might be used in order to meet specified strength, flexibility, or thermal resistance requirements.

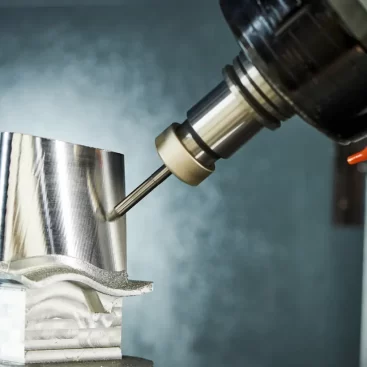

CNC Machining: Aluminum rapid prototyping is commonly done through CNC (Computer Numerical Control) machining. By computer controlling the milling, drilling, and cutting of the aluminum into the desired shape, this process is performed using computer controlled tools. CNC machines have very small tolerance to date and are accurate up to high level.

Casting and Molding: For some designs, the prototype can be made by aluminum casting, such as sand casting or die casting. However, these methods are particularly useful for complex parts and an alternative to CNC machining for building the prototype, but on a larger scale.

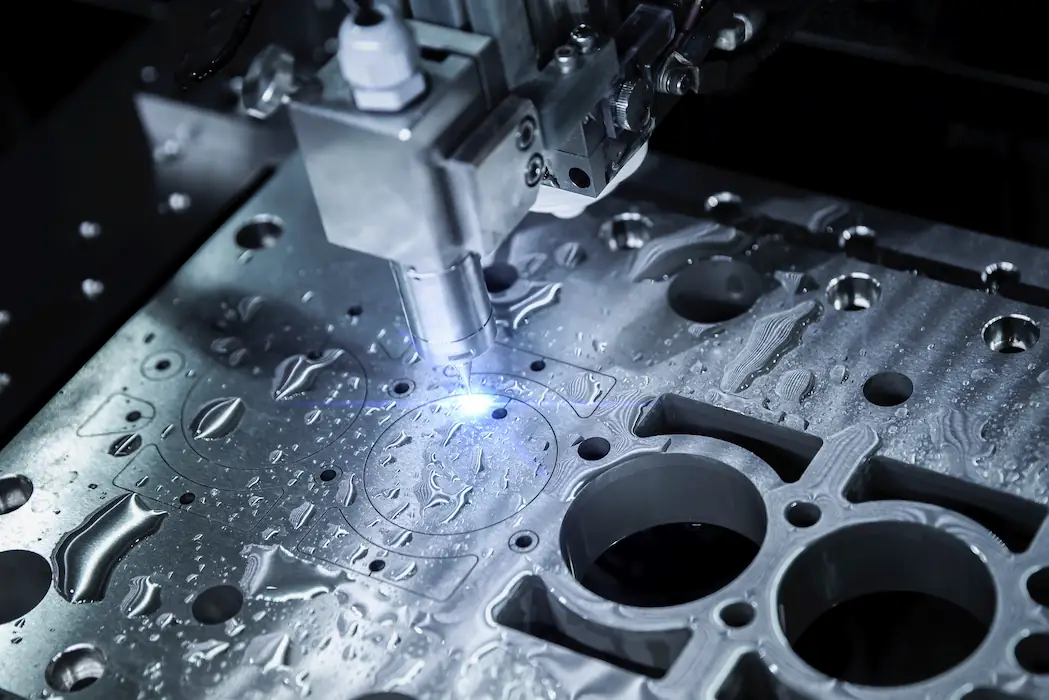

3D Printing (Selective Laser Melting): While not as commonly used as other materials, Selective Laser Melting (SLM) enables us to print a complex piece of aluminum that is both light and relatively strong as it prints aluminum powder as a layer by layer process. Producing parts with internal structures that are difficult to produce by conventional machining are highly suitable for SLM.

Post-Processing: Once the prototype is formed, more post-processing techniques are used to get the final part to have a nicer aesthetic and or quality. It may be polished, anodized (for improved corrosion resistance) or surface finished, or have coatings added for further durability or aesthetic appeal.

Testing & Evaluation: After finalizing the prototype, it tests to ascertain if it meets design and function requirements. It identifies parts that can be improved, and that need to be modified before going into mass production.

Aluminum Rapid Prototyping Advantages for You

DUNTEK’s Aluminum Rapid Prototyping Service offers several distinct advantages:

High Precision and Quality: All our aluminum prototypes are made with CNC machining, which allows us to create models with precise tolerances, which means each part will exactly fit the designed shape. We are capable of delivering prototypes as accurately as with advanced machines and skilled engineers.

Wide Material Selection: DUNTEK provides a broad array of aluminum grades developed to satisfy strength, flexibility, and corrosion resistance requirements. This material flexibility allows clients to choose the ideal alloy to meet their specific requirements, whether they prioritize strength, weight, or conductivity.

Fast Turnaround: We at DUNTEK recognize that prototyping speed is essential. Our streamlined processes enable us to provide rapid turnaround times, allowing clients to iterate and improve designs efficiently.

Experienced Team & Innovation: Our team of engineers and machinists has years of experience in the field, and collectively bring a vast body of knowledge to each project. We continuously invest in the latest technologies and methods, ensuring our clients receive cutting-edge solutions tailored to their needs.

Comprehensive Testing & Quality Control: We conduct extensive quality checks throughout the prototyping process to ensure that each part meets both DUNTEK’s and our clients’ standards. We also have strict quality control processes in place, guaranteeing that we produce prototypes that exceed expectations – if not the expectations.

How We Meet Client Needs for Aluminum Rapid Prototyping

DUNTEK is committed to delivering a client-focused aluminum rapid prototyping service that emphasizes collaboration, customization, and efficiency:

Customized Solutions: We work closely with our clients to understand their unique requirements and offer customized prototyping services tailored to their design and application needs. From specific material grades to precise finishes, DUNTEK adapts every aspect of the prototyping process to meet client specifications.

Ongoing Communication: We maintain transparent communication throughout the project, ensuring clients are informed at every step of the process. We are on call to help out with updates, tech support and guidance to help make your prototyping experience as smooth and as collaborative as possible!

Flexible Production Capabilities: For smaller project sizes, DUNTEK provides prototyping service for single prototype, up to small batch production runs. When we validate the prototype, we can easily scale up to production, a glitch free move from prototype to manufacturing should we need it.

Focus on Innovation: Innovation is at the heart of what we do, so we’re constantly looking at new materials, new techniques and new technologies in aluminum prototyping. This commitment allows us to offer creative solutions and cutting-edge prototypes that help clients stay ahead in competitive industries.

Conclusion

DUNTEK’s Aluminum Rapid Prototyping Service combines advanced technology, high-quality materials, and a client-centered approach to provide prototypes that meet and exceed industry standards. If you require a one-off prototype, want to produce parts in large volume or any stage in between, DUNTEK has the experience, technology, and resources at our fingertips to meet your brief with velocity and precision.