Aluminum casting machining is a specialized process that combines aluminum casting with precise machining techniques to create components that are strong, lightweight, and dimensionally accurate. It is a widely used process across many industries, such as the automotive, aerospace, electronics and industrial machinery industries, for example, where the materials that are being manufactured must withstand intense wear and operate in high pressure environments.

Understanding Aluminum Casting Machining: How It Is Used in Manufacturing and What It Provides.

Aluminum casting machining is a specialized process that combines aluminum casting with precise machining techniques to create components that are strong, lightweight, and dimensionally accurate. It is a widely used process across many industries, such as the automotive, aerospace, electronics and industrial machinery industries, for example, where the materials that are being manufactured must withstand intense wear and operate in high pressure environments.

Aluminum is special due to its unique properties in the world of manufacturing. It is lightweight, but strong, resistant to corrosion, and excellent thermal and electrical conductivity. When properly cast and machined, aluminum components can fulfill high performance industry’s exacting requirements and hence provide applications where weight savings can be gained without sacrificing durability or resilience.

The significance of aluminum casting machining extends beyond just producing high-quality parts; it’s an essential process in advancing engineering applications where precision and customization are key. Using this process lets manufacturers attain specific tolerances that couldn’t be had with raw aluminum casting to open up new designs, efficiencies, and scalability.

The Process of Aluminum Casting Machining: How Do We Make Sure Of High Precision And Quality

At DUNTEK, we follow a meticulous, multi-stage aluminum casting machining process designed to maximize precision, efficiency, and consistency. Here’s an in-depth look at how we transform raw aluminum castings into high-quality, fully functional components:

Casting the Raw Part: Cast phase is the beginning of the process. But aluminum is cast by sand casting as well as die casting. More complex shapes need the support of sand casting and steeper production runs should be reserved for die casting as it entails increased precision and fewer cycle times. The machining requirements stem from these first choices.

Initial Inspection and Preparation: After the aluminum casting is complete, we test it for any poor casting or deviations that will affect the machining phase. This inspection is to see if each cast passes according to our quality standards. It involves cleaning up the material, setting up the part for milling.

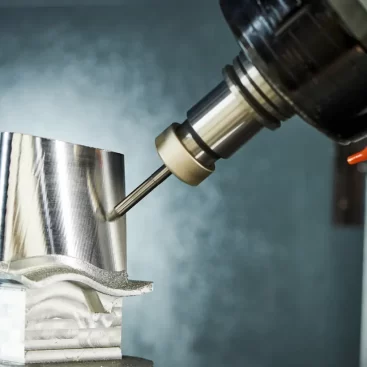

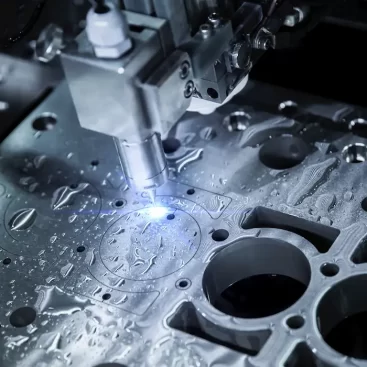

Precision CNC Machining: Once the cast is ready we tow to CNC (Computer Numeric Control) machining where our equipment performs high precision cutting, drilling contouring. The advantages of CNC machining are a big part of working with extremely tight tolerances and complex geometries, which are necessary to fulfill the unique needs of industry, such as aircraft and automotive, in our aluminum casting process. If you are interested in more about our CNC machining services, please visit CNC machining page.

Deburring and Polishing: Deburring is also very important, that means after machining any sharp edges, burrs, or extra material left behind have to be removed. This step helps to keep safety standards as well as a smooth finish. Next, we polish the component to get a clean, professional looking part which may be significant for a consumer facing application or part visibility.

Surface Treatment and Coating: they also come in anodized or powder coated, depending on how you’ll use the component. Anodizing put a protective oxide layer on to increase corrosion resistance and surface hardness, and powder coating adds a durable surface that may have an improved cosmetic appearance. These last steps make sure that the aluminum part not only works well now, but keeps working properly across time.

Each of these stages involves rigorous quality control checks, guaranteeing that our aluminum casting machining process consistently delivers components of the highest quality.

Our Advantages in Aluminum Casting Machining

DUNTEK’s approach to aluminum casting machining is built on several key strengths that set us apart:

Advanced Machinery and Technology: We use latest in CNC machinery and casting equipments to handle complex shapes and designs, meet high tolerances and deliver. Being able to handle a variety of project requirements with our range of technological investments, from simple to complex parts.

Experienced Team: Skilled machinists and engineers make up the core of our team, each with years of experience on every project. With this expertise, we’re able to fix problems efficiently, adjust our process where necessary and also guarantee that every part complies with exact specifications. Along with that, we also believe in staying updated with the newest things in the industry so that our team never stops learning.

Flexibility and Scalability: Every project is different and this is something we know, we pride ourselves that we can bend. We are flexible whether they are coming to you for a small prototype run, or a large production order. This scalability is a significant advantage for clients looking to partner with a reliable manufacturer for both short-term and long-term projects.

Commitment to Quality and Sustainability: At every stage of our process we give quality control a strong precedence, and we keep waste, energy to a minimum in terms of being sustainable. Our continued dedication to doing things the right way involves aligning our practices to the latest environmental standards. For more information about who we are and our core values, click here.

Meeting Client Needs with Tailored Aluminum Casting Machining Solutions

Our approach to aluminum casting machining is designed with the client in mind. We know that each project has unique needs, from exact dimensions to performance criteria, and we spend time to learn these details inside out.

Here’s an example of how we approach a client project: For example, recently we worked on an electronics sector company who needed to light weight aluminum casings that effectively transferred heat. To meet the thermal management, protective function, and structural rigidity requirements for this company’s enclosure, this enclosure had to be strong and restrain sensitive components. We worked with them closely to refine the design, picking a particular aluminum alloy that provided the right amount of strength and thermal conductivity. Additionally, we underwent a custom surface treatment on top of this to kick up the part’s durability and aesthetic enjoyment.

We define our client relationships with this level of customization. We believe that strong partnerships are based in open communication, transparent processes and a sincere commitment to quality. From the initial consultation to final delivery, our team keeps clients informed and engaged every step of the way, ensuring they feel confident in the final product. Our FAQ page provides answers to common questions and offers additional resources for those considering aluminum casting machining for their projects.

Besides scaling down, we also stress the speed of execution. We’re able for many industries to achieve rapid turnarounds without compromising on quality. For clients in fast-paced industries, our ability to combine precision with speed is a major advantage.

Partnering with Us for Your Aluminum Casting Machining Needs

At DUNTEK, aluminum casting machining is more than a technical process; it’s a craft we continually refine to meet the evolving demands of modern manufacturing. With the use of advanced equipments, industry expertise and with a client oriented attitude, we combine them together to offer high quality and reliable and yet tailored machining solutions.

You can explore further how our services can help you to bring your projects to life, and we’d love to help you! If you would like to know more about our services, you can visit our services overview page or give us a ring on our contact page. Let us be the partner you can rely on for precision, quality, and innovation in aluminum casting machining.