CNC Rapid Prototyping Service refers to the use of computer numerical control (CNC) machining technology to create rapid, functional prototypes. Typically, these prototypes are made of durable materials (metal, plastic, composite materials) and look like the final products in form with form, fit, and function. CNC rapid prototyping allows companies to quickly test and refine their designs so they can go into mass production fully prepared. For such industries automotive, aerospace, industrial consumer electronics, industrial machine, design accuracy and testing are most important so they need this kind of service.

1. What is CNC Rapid Prototyping Service?

CNC Rapid Prototyping Service refers to the use of computer numerical control (CNC) machining technology to create rapid, functional prototypes. Typically, these prototypes are made of durable materials (metal, plastic, composite materials) and look like the final products in form with form, fit, and function. CNC rapid prototyping allows companies to quickly test and refine their designs so they can go into mass production fully prepared. For such industries automotive, aerospace, industrial consumer electronics, industrial machine, design accuracy and testing are most significant so they require this kind of service.

2. How to Make CNC Rapid Prototyping: The Process?

The CNC rapid prototyping process involves several key stages:

Design and CAD Modeling: First step begins with designing the prototype in a CAD (Computer-Aided Design) software. 3D models are detailed and include, among other features, dimensions, material properties.

Material Selection: Next to selecting the correct material after the design gets finalized is finalizing the prototype. They can be metals (aluminum or stainless steel); plastics (e.g., ABS, polycarbonate, nylon) — depending on what is required in your application.

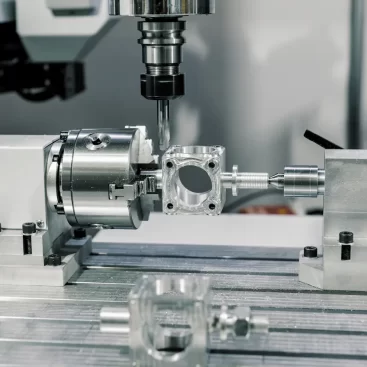

CNC Machining: When it has been decided to design and material, the prototype is made using a CNC machine. Computerized machining (CNC) refers to the use of computer controlled tools to cut, mill, or drill material to the design specifications. The process of early prototyping is called rapid prototyping, and it tends to be done hours or at most days, depending on the complexity.

Post-Processing: The prototype once machined then may need post-processing for a smooth finish to the surface or for the addition of threading or painting. Post-processing techniques are sanding, polishing, coating, and heat treatment usually.

Testing and Evaluation: After the prototype is created, it is tested to determine that it works as it should, is accurate and function(s) as it should. This is important because you have to test and see whether there’s any design flaws or there are any areas that require improvement before you really go into mass production.

Refinement and Iteration: According to the results of the testing, the design will be corrected, the prototyping cycle can be repeated until the required functionality is achieved. It provides a chance to continuously improve and optimize the final product.

3. DUNTEK’s Advantages in CNC Rapid Prototyping

DUNTEK stands out in the CNC rapid prototyping field because of the following advantages:

Advanced Technology and Expertise: To do this, we use state of the art CNC machines and CAD/CAM technology to make very accurate prototypes. The parts are manufactured to a precision by our skilled engineers and machinist so that each part meets our strict specifications and are ready to go inside.

Material Flexibility: At DUNTEK, we can work with a wide variety of materials, including metals, plastics, and composites, giving our clients the flexibility to select the best material for their specific needs. We have broad material options that we can offer, both to industries that require unique performance characteristics.

Quick Turnaround Time: Speed of production is one of the main advantages of using CNC rapid prototyping. DUNTEK offers rapid turnaround times, often completing prototypes within a matter of days, allowing our clients to move quickly from the design phase to testing and production.

Precision and Quality Control: DUNTEK set the bar for the highest standards, we promise to manufacture each and every prototype with the commitment to produce at the highest achievement of quality. Our CNC machines are calibrated for precision, and we have a rigorous quality control checks in the production process.

Cost-Effective: By utilizing CNC rapid prototyping, clients can significantly reduce the costs associated with traditional prototyping methods, such as handcrafting or injection molding. It also helps reduce time to market by allowing for businesses to test their products and change them around without incurring large upfront investments.

Scalability: DUNTEK can cover small batch of prototypes or large production run according to your need. We have CNC equipment that handles large and small, complex parts, so whether you have a small or large project, we can work with you.

4. How We Satisfy Our Clients in CNC Rapid Prototyping

At DUNTEK, we understand the importance of delivering prototypes that not only meet but exceed our clients’ expectations. Here’s how we cater to our clients’ needs:

Tailored Solutions: We provide customized prototyping services based on our clients’ specific product requirements. With years of experience, DUNTEK guarantees that each and every prototype is tailored to meet the exact client’s specific needs; be it for any intricate designs, material selection, or achieving a certain tolerance level.

Collaboration and Communication: We maintain open and frequent communication with our clients throughout the prototyping process. Our team works closely with clients to understand their vision, offer technical advice, and ensure that the prototype aligns with their design goals.

Rapid Response and Support: Product development often occurs in an order in which time is of the essence. DUNTEK’s CNC rapid prototyping service offers quick response times, enabling clients to rapidly iterate their designs. Furthermore, our customer support team will be available to help solve your needs when the process goes awry.

Prototyping and Beyond: DUNTEK not only prototypes, we provide a full spectrum of services including small batch production, full scale manufacturing, as well as post-production support. This means that once the prototype is validated, clients can seamlessly transition to full production without having to find a new supplier.

Competitive Pricing: We strive to offer competitive pricing for our CNC rapid prototyping services, ensuring that businesses of all sizes can access high-quality prototypes without breaking the bank. We’re transparent about our pricing, which are cost-effective without compromising on quality.

5. Conclusion

When you select DUNTEK for your custom CNC rapid prototyping requirements, you get access to state-of-the-art technology, seasoned experience and a commitment to its clients in every project. From the automotive, aerospace, medical or consumer product industry, DUNTEK will provide you with a quick, accurate and low cost prototype creation to move you from concept to reality quicker than ever before. Any further questions? Get in touch now!