CNC (Computer Numerical Control) machining is an integral part of the precision manufacturing world that helps to create extremely accurate and complicated parts throughout industries like aerospace and medical devices. The precision machining of aluminum and soft metal parts even becomes more critical than it otherwise would. Although easier to machine compared to harder metals such as steel or titanium, you can’t machine them right if you don’t have the utmost precision when it comes to performance, durability and aesthetic finish.

What Are Aluminum And Soft Metal Precision CNC Machining Parts?

CNC (Computer Numerical Control) machining is an integral part of the precision manufacturing world that helps to create extremely accurate and complicated parts throughout industries like aerospace and medical devices. The precision machining of aluminum and soft metal parts even becomes more critical than it otherwise would. Although easier to machine compared to harder metals such as steel or titanium, you can’t machine them right if you don’t have the utmost precision when it comes to performance, durability and aesthetic finish.

The industry processes that use aluminum find this element lightweight, corrosion another high demand are soft metals such as brass, copper and zinc for their conductivity, malleability and suitability to be used in the applications such as heat exchangers and connectors.

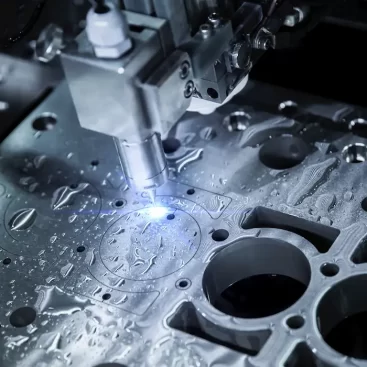

Our precision CNC aluminum and soft metal machining utilizing high-tech machinery cuts, mills, and shapes aluminum and soft metals into complex, tight tolerance parts meeting defined industries standards. Being able to effectively machine these metals is crucial in order to achieve performance and longevity in the finished component resulting from these sectors, where weight reduction, heat resistance, and electrical conductivity is paramount.

These materials are key to virtually every manufactured part, from engine components and engine fittings, housings, heat sinks, and extremely complex electronic devices that demand highly specified features to operate properly.

Precision Aluminum And Soft Metal CNC Machining – How We Achieve It

Our precision CNC machining services for aluminum and soft metals are our specialty at DUNTEK. Our machining process for these materials is designed to achieve tight tolerances and flawless finishes that meet the rigorous requirements of our clients. The main steps in our machining process include:

Material Selection and Preparation: Firstly, the material which is to be machined for the project has to selected. We take care to choose the proper alloy or grade for aluminum and soft metals when the requirements of the part are to be manufactured. We have quality checks over materials we supply from trusted suppliers that fit industry standards, before they then enter into machining.

CNC Milling and Turning: For aluminum and soft metal machining, we use CNC milling as the main method. Using multi axis CNC machines, we are capable of making complex shapes and contours that are hard or impossible to create on manual machining. In turning operations, we use CNC lathes to rotate the material into the exact form we want it to take; that is for turning operations. For parts such as shafts, bushings, and rings, this process is very effective at ensuring that all the parts are both dimensionally accurate and smooth.

Precision Cutting and Drilling: The material is cut to a size by precision cutting tools, and special drills are used to create holes to very high precision. These tools operate at amazing speed and accuracy, enabling small features like threaded holes, deep pockets, and grooves to say exactly what they are supposed to.

Surface Finishing: Aluminum and soft metal parts are often machined and then require a final surface treatment to improve their appearance and performance. We offer anodizing, powder coating or polishing finishing. These processes provide a material with better corrosion resistance, surface hardness and aesthetic appeal, as well as improved functionality in heat sinks, housings, and connectors.

Quality Control and Inspection: Quality is a high priority throughout the machining process. Not only do we test every part using advanced inspection techniques such as coordinate measuring machines (CMM) and laser scanning to verify dimensional accuracy, but we also employ such testing to locate any deviation from what has been previously tested, for comparison. It makes sure that any component, be it a complex aerospace fitting, or a simple automotive part, meets the required specifications and tolerances. The precision level we maintain ensures that the end product is ready for use in the most unforgiving applications.

What makes us different from other Aluminum & Soft Metal CNC Machining?

With an accumulation of modern tech, their experience, and unwavering determination to flawless items, DUNTEK has formed its way as a front-runner in hard and soft metal precision CNC machining. Here’s why our customers trust us with their most challenging projects:

Cutting-Edge Technology: Our latest CNC machining technologies include high speed milling machines, precision turning lathes, and we are able to tackle the most intricate designs. Faster turnaround times, higher efficiency, and better part quality are all thanks to our investment in the latest machines. What makes us unique in the industry is the ability to machine so many types of soft metals to such a high level of precision.

Skilled and Experienced Team: DUNTEK team is made up of talented engineers and machinist that have years of experience in precision CNC machining. Additionally, our team members are cognizant of aluminum’s and soft metal’s unique characteristics, which enables their development of machining processes that are maximally efficient and minimally wasteful.

Customized Solutions for Diverse Industries: Whatever industry you are in: aerospace, automotive, medical devices, whichever you can find we must have a solution. For instance, in the past we would build for an aerospace client high strength, lightweight aluminum parts for an aircraft engine. With the right material and the most advanced machining technique available, we were able to help our client lower the weight of the part, while retaining part integrity, improving the engine performance and fuel efficiency.

Commitment to Sustainability: We aim to minimize DUNTEK’s impact on the environment at and responsible for manufacturing. In order to minimize waste, we take advantage of energy efficient machinery, recycle metal and use ecologically friendly coatings and surface treatments. Our philosophy of focused sustainability meant that machining operations adhered to industry best practice for environmental responsibility.

Precision and efficiency meet the needs of the Client.

When it comes to aluminum and soft metal CNC machining, we understand that our clients have unique needs. We are committed to delivering the highest level of service when it comes to having to deal with parts of more or less complex geometry, use of lightweight materials or should it be parts of specific surface finishes. Here’s how we meet our clients’ needs:

Tailored Project Management: On each client we work very closely with in order to understand what they really require and provide a solution which best fits their time frame, budget and technical requirements. We make sure each project goes without a hitch from the start to the end of the project.

Rapid Prototyping: Rapid prototyping is absolutely necessary in many industries for testing designs prior to starting full scale production. DUNTEK excels in providing fast, high-quality prototypes for aluminum and soft metal parts, allowing our clients to validate designs quickly and move forward with confidence.

High-Volume Production: Precision is always our goal, but we also are capable of high volume production runs. We use our automated CNC machines to produce massive quantities of parts with consistent quality and Acmes to fulfill high volume manufacturing.

Timely Delivery: In many industries, time is of the essence. But we work hard to make sure your parts arrive on time – every time — as you need them. Whether it’s a small order or a big project, we make sure to turn it around fast, without giving up on the quality.

Aluminum & Soft Metal CNC Machining Trends – External Insights

Due to industrial appetite for lightweight, corrective, and economical solution, the demand for aluminum and soft metal parts is increasing. The globalization trend is also expected to expand the demand growth of CNC machining market as stated by a recent Grand View Research report.

Additive manufacturing and hybrid machining are also catching up to the trend in the machining of aluminum and soft metals. Complementary to traditional CNC machining, these technologies allow more complex geometries without necessarily consuming excessive material. As these technologies evolve, DUNTEK is exploring how we can incorporate them into our workflow to provide even more advanced solutions for our clients.

Conclusion: Aluminum & Soft Metal Machining Precision & Excellence From DUNTEK

DUNTEK comes with the precision and proficiency to machine high quality aluminum and soft metal parts for numerous industries. If you work in aerospace, automotive, or electronics, you can depend on our commitment to provide superior CNC machining services–making sure that your components meet the highest quality, performance, and reliability levels.

If you’d like to know more about how we might be able to help with your next machining project, please visit our services page, or contact us directly for more information about our capabilities and solutions.