What Are CAD/CAM Machining Services?

The CAD/CAM machining, described above, is an integration of two critical technologies — Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) which facilitate the design and manufacturing processes. In these services, manufacturers can create perfect, complicated parts with high efficiency and precision.

CAD: With this software, designers can build 2D and 3D models of the parts that will be produced. These models are a blueprint for the entire production process, bringing function and manufacturability together.

CAM: CAM software translates the CAD models once a design has been completed into machine-readable instructions. These instructions tell CNC (Computer Numerical Control) machines what to do in the production of the part so that they will produce it accurately every time.

At DUNTEK, we specialize in providing advanced CAD/CAM machining services, using these technologies to produce high-precision parts for industries ranging from aerospace to automotive, medical devices, and electronics. We make use of CAD/CAM to not only ensure very fast and very true manufacturing process, but also incredibly economical.

How Do CAD/CAM Machining Services Work?

The CAD/CAM process consists of several various steps, each aimed into achieving the high level of precision and quickness of the final product. Let’s break down the process:

Design Phase (CAD): They start at the first step of which is making a detailed design using CAD software. When engineers and designers work together during this phase, we simulate parts, establish their geometry, dimensions, and material requirements. With CAD software you can easily change things with every real time the then see and try it out different ways before finally deciding to design it. As long as there is a simple part or a complex, multi-framed assembly, we use CAD to ensure the design is correct, correct, and serviceable. (For more information about our CAD/CAM Services).

Programming (CAM): When the design is done, the CAM software kicks in. Gives the cad model of the part ‘into instructions’ (G-code) the CNC machine can follow. With the CAM system, our engineers can test out the entire machining process to see whether there are any possible tool collisions or inefficiencies. The most important part performed is the tool path optimization and the machine settings to have minimal waste and faster cycle time.

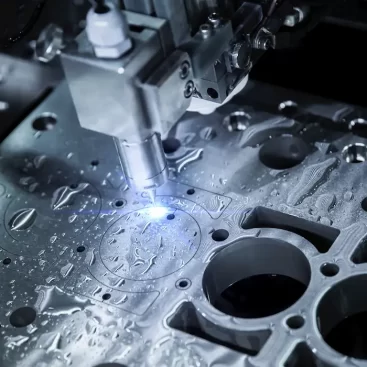

Machining Process: Our CNC machines are set up by the CAM software to produce the part based on the instructions generated. The part requirements dictate which machine we use for a part, whether it is milling machines, lathes or we use a multi axis machine. The fine and complex geometries or the narrow tolerances are efficiently processed by CNC machining because of its high precision. From this point on, the material is shaved away in layers based upon the part design.

Post-Processing and Quality Control: Parts are carefully inspected for machined accuracy, and quality in accordance with required tolerances. Moreover, we employ advanced measurement tools (CMM/Coordinate Measuring Machines, and laser scanning) to verify the accuracy of each part. In addition, we also provide post-processing service like polishing, anodizing or coating to get better surface finish and performance for the part, as necessary (more details please refer to our factory page).

Why Choose CAD/CAM Machining Services?

There are several key advantages to using CAD/CAM machining services that make them the preferred choice for precision manufacturing. Here’s why we recommend CAD/CAM machining for our clients:

Enhanced Precision and Accuracy: CAD/CAM technology permits very tight tolerances and a complex geometry that otherwise would be difficult and often impossible to achieve by hand. It’s particularly useful in industries like aerospace or medical devices where parts need to be to absolute standards.

Reduced Production Time: CAD/CAM machining significantly reduces the time it takes to create a part to the point of automating the design to production workflow. Additionally, our engineers’ ability to simulate the machining process beforehand means that we can see potential problems before they happen, and be prepared to minimize downtime and errors.

Cost Efficiency: CAD/CAM technology does involve an initial cost of software and equipment; however, the long term savings involved make it worthwhile. This enables more cost-effective manufacturing process as we can optimize tool paths, reduce material as well as human labor. The faster speeds and fewer errors also means more production cycles, which cuts down on cost.

Flexible Customization: With CAD/CAM, we can take on just about any material, part complexity. CAD/CAM machining is flexible enough to produce simple components or highly customized designs, so whether you need parts or large assemblies, this machining option can almost always lead to the desired result. Changing the design or machining process requires no special tooling, and we make changes easily as requirements change so that your final product meets your specifications.

Streamlined Communication: Using CAD/CAM software provides a clear visual representation of the part, making it easier to communicate with clients and manufacturers. Designers, engineers, and clients can collaborate in real-time, which reduces misunderstandings and helps to ensure that the final product aligns with expectations.

How We Meet Our Clients’ Needs with CAD/CAM Machining Services

At DUNTEK, our CAD/CAM machining services are designed to meet the unique needs of our clients, whether they are developing prototypes, manufacturing large batches, or creating highly specialized parts for a specific industry. Here’s how we serve our clients:

Rapid Prototyping: This is why we do rapid prototype your designs using our CAD/CAM technology? This allows clients to test and refine their designs before committing to full-scale production, saving time and money.

High-Volume Production: Once the prototype is validated, we can move directly to high volume production, where we can take advantage of low cost mass production, yet without sacrificing quality. Whether you’re making a few parts or thousands, your parts will always meet the required specifications because of our advanced machinery and optimized processes.

Customization: Whether you require intricate features or specific materials, our CAD/CAM machining services are highly customizable. We work with clients to ensure that every aspect of the design is tailored to their requirements, including material selection, surface finishes, and machining processes.

On-Time Delivery: And we realize that deadlines matter. With our efficient use of CAD/CAM technology, we deliver parts on time and ready to go into your application.

External insights into CAD/CAM Machining

As industries evolve, the role of CAD/CAM machining services continues to grow. As one of the Engineering.com CAD/CAM software study points out, CAD/CAM software is getting more and more sophisticated – offering advanced features such as additive manufacturing features and simulating tools. These innovations improve the precision achievable by manufacturers and improve the processes of production even further.

All of this is being influenced by the rise of Industry 4.0 where IoT (Internet of Things) and automation meet, — specifically with CAD/CAM machining. By connecting machines to the cloud, manufacturers can be in the loop with real time monitoring of processes, tracking of performance, and data driven decisions around production optimization. (For more on CAD/CAM technologies, see engineering.com)

CAD/CAM Machining Can Effectively Boost Your Manufacturing Procedure

At DUNTEK, we believe that CAD/CAM machining services are the cornerstone of modern manufacturing. By integrating cutting-edge software with state-of-the-art machinery, we provide clients with precision, efficiency, and cost-effectiveness in every part we produce. Whether you’re looking to manufacture aerospace components, automotive parts, or medical devices, our CAD/CAM machining services offer the solutions you need to take your designs from concept to reality. Click here to get started!