Laser machining and welding have changed the face of aerospace industry by making possible the precision cuts and join of materials under strict tolerance. These laser based methods are critical in aerospace, where material integrity and precise measurement are as essential as stronger, lighter materials that improve aircraft performance. The precision this technology provides allows it to offer a distinct edge in manufacturing, enabling it to compete with other machining methods at mastering the intractable geometric complexity and ultra-thin geometry often employed in aerospace design (source).

What Is Aerospace Laser Machining and Welding?

Laser machining and welding have changed the face of aerospace industry by making possible the precision cuts and join of materials under strict tolerance. These laser based methods are critical in aerospace, where material integrity and precise measurement are as essential as stronger, lighter materials that improve aircraft performance. The precision this technology provides allows it to offer a distinct edge in manufacturing, enabling it to compete with other machining methods at mastering the intractable geometric complexity and ultra-thin geometry often employed in aerospace design (source).

The demand for aerospace laser machining and welding is on the rise due to the industry’s reliance on materials such as titanium, aluminum, and advanced alloys, which must endure extreme conditions like high temperatures and pressure. Laser use by aerospace manufacturers allows for high precision cuts, tight welds, and strong bonds with minimal thermal distortion, a capability lacking in many traditional methods.

How We Ensure Precision in Aerospace Laser Machining and Welding

At DUNTEK, our aerospace laser machining and welding processes combine cutting-edge technology with careful planning to meet stringent industry standards. Here’s a breakdown of our approach:

Material Preparation: First and foremost, we examine thoroughly the material type, thickness, and tolerance requirements. Eye-opening: Laser settings for materials such as titanium and aerospace grade alloys have to be carefully set to avoid micro cracking or heat induced distortion. In this step, we precisely calibrate such that each material is machined or welded to optimal laser parameters.

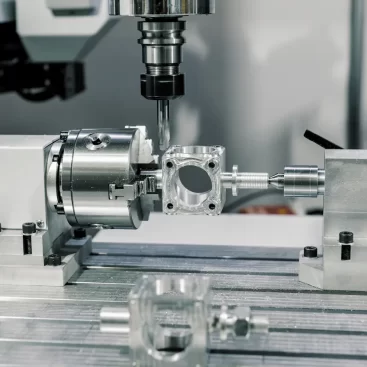

Laser Machining: We cut materials into complex shapes with sub millimeter accuracy using high intensity laser beams. The process minimizes the heat affected zones, while preserving the structural integrity of the material. Our CNC guided laser systems make it possible to create intricate designs that would be difficult otherwise for aerospace components (our CNC machining page).

Laser Welding: In laser welding, we use the focused laser beam heat to weld with precision, avoiding contact. The control of weld size and penetration depth thus provided by this method is excellent for applications in aerospace where joint strength is critical. Our laser welding techniques, by minimizing material deformation, yield seamless connections that are able to withstand high stress environments.

Quality Assurance and Testing: We do rigorous tests on each component, no exceptions, testing visually, strength wise, or dimensional errors. This multistep quality control process is behind every product we deliver that meets aerospace standards, meaning safety and longevity in flight.

Our Advantages in Aerospace Laser Machining and Welding

DUNTEK’s approach to laser machining and welding brings multiple advantages to aerospace clients:

State-of-the-Art Equipment: Our precision and repeatability is accomplished using advanced laser systems that are designed for these types of high tolerances. These systems allow us to deliver products which meet current industry standards as well as new aerospace programs (our factory).

Skilled Engineering Team: We are engineers and machinists who’ve been around the aerospace manufacturing game. And this expertise means we tailor our processes for each client, tuned to ways that will maximize things like thermal resistance and material strength.

Commitment to Sustainable Manufacturing: Energy intensive processes are commonplace in the aerospace manufacturing business, but our use of laser technology is low waste and low energy use. This is in line with global environmental goals, and aligns to the industry’s movement towards more environmentally friendly manufacturing (our philosophy).

Rapid Turnaround and Scalability: Thanks to our fast technology, we can offer you great speed with quality eliminated. This capability is especially beneficial for aerospace clients facing tight deadlines.

How We Tailor Solutions for Aerospace Applications

Our approach to aerospace laser machining and welding is highly customizable, designed to address specific challenges that each client may face. Let’s say working with a recent defense client, we were producing lightweight, high-strength components for an aircraft program. Each component was required to be strong and light, and welds able to withstand extreme stress and temperature fluctuations, all of which needed to be met as exacting standards as possible.

Therefore, we worked with the client’s engineering team to adjust our laser parameters for each weld, with penetration depth and energy level tailored so that each weld could meet these requirements. Further, we subjected the components to fatigue testing to replicate real life stresses and determined how components would behave over time. Sharing resources allowed us to meet the client’s expectation; on time, on budget and great product, reliable and durable.

One use case that ties in is the client implementing a specialized laser cut for high precision turbine components. To meet the necessary aerodynamic shape, we were able to spare the structural strength of the component, by using high power lasers capable of ultra-thin cuts. One of the things that make us your preferred partner to do complex aerospace manufacturing projects is our ability to adapt as needed and optimize for specific projects.

DUNTEK Has An Edge to Deliver All Aerospace Projects

In the aerospace industry, DUNTEK understands the specific specifications and requirements and the paramount importance of durability, precision, and efficiency in each component. Our aerospace laser machining and welding services combine advanced technology with a client-centered approach, ensuring that we deliver parts tailored to each project’s specific needs.

Visit our services page for more insights on how we can help with your aerospace manufacturing projects, or reach us via our contact page for any specific query. If you have a new prototype or require a dependable partner for mass production, we’re ready to assist you succeed. Click to ask a question or require a quote!