CNC Casting Machining is a specialized manufacturing process that combines traditional casting techniques with precise CNC (Computer Numerical Control) machining to create highly accurate and complex metal parts. The process begins with casting a metal part into a near net shape process using other means such as sand casting, investment casting, die casting and machining it to the final dimensions, features and surface finish using CNC. This hybrid approach has become widely used in automotive, aerospace and industrial machinery industries because durability, precision and complex geometry require this.

What is CNC Casting Machining?

CNC Castings Machining is a specialized manufacturing process that combines traditional casting techniques with precise CNC (Computer Numerical Control) machining to create highly accurate and complex metal parts. The process begins with casting a metal part into a near net shape process using other means such as sand casting, investment casting, die casting and machining it to the final dimensions, features and surface finish using CNC. This hybrid approach has become widely used in automotive, aerospace and industrial machinery industries because durability, precision and complex geometry require this.

How to Make CNC Casting Machining: The Process

Creating components through Castings CNC Machining involves a series of specific steps that blend traditional and modern manufacturing techniques:

Casting Process Selection: Different casting methods are used depending on requirements, material used and design. Sand casting is a very versatile way to cast large parts, Die casting is good for high volume and smooth surface and Investment casting is good for detail parts with high accuracy.

Mold Creation: Once the casting method is figured, molds are produced from the initial design in 3D. These molds are what give the base shape of the part, molten metal goes in there and takes its desired shape. This is certainly necessary to determine the base geometry of the part.

Pouring and Solidification: Then the chosen metal be it aluminum, steel or whatever the alloy is melts and is poured into the mold. When it cools and solidifies, it returns to the general shape of the part as intended in the mold.

Initial Inspection and Cleanup: Then the part is cast, inspected, excess material removed. At this stage, we clean up any casting imperfection like burrs flashing to ready the part for CNC machining.

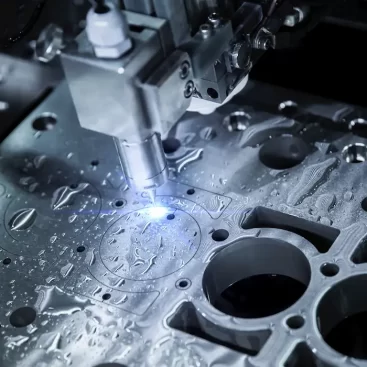

CNC Machining Process: After, we cast the part and clamp it down onto a CNC machine where it’s precision machined. However, the CNC process does not stop there and fine-tunes the dimensions, drills holes, smoother on surface as well as adds sophistication features to the exact specifications. The step so tight tolerances, smooth finishes and close tolerances that the casting process alone could not provide.

Quality Control and Testing: After which the machined piece is inspected and quality control to ensure that things like sizes, tolerances and how the machined piece can be considered a quality piece are confirmed. Methods can be tested by using dimensional analysis, surface finish checks, and functional testing to prove the part is made in accordance to what is intended.

Our Advantages in CNC Casting Machining

DUNTEK’s Castings CNC Machining service provides unique advantages that set us apart in the industry:

Precision and Complexity: Through our CNC machining process, we can add all the intricate details and the exact measurements required for casting, bringing you parts that meet the most strict industry standards. We can garment complex shapes to a higher degree of accuracy, combining casting with machining.

Material Versatility: We produce accessories using a variety of materials, including aluminum, stainless steel and specialty alloy. That flexibility enables us to serve many industries and applications, offering a different tailored solution from each customer.

Efficient Production for High Volume Needs: We can process both small and large volume product runs. By utilizing both casting and CNC machining, we can achieve cost-effective production without compromising quality, making us an ideal partner for clients with high-volume needs.

Skilled Workforce and Advanced Equipment: And with our team of experienced machinists and engineers, and our state of the art CNC machines, every part that is produced from their casts is top of the line in quality and precision. We invest in technology and training to ensure that we stay at the cutting edge of what’s possible in casting and CNC machining.

How We Meet Client Needs in CNC Casting Machining

DUNTEK is committed to providing client-focused solutions in Castings CNC Machining by prioritizing customization, quality, and efficient production:

Customizable Solutions for Different Industries: We provide flexible casting and machining services that can accommodate different industry needs like aluminum castings for aerospace and stainless steel parts for automotive. It makes this adaptability possible, so we can adapt to a sector’s requirements with exactness.

Collaborative Approach: From the initial design phase to final inspection, we work closely with clients to understand their project goals, challenges, and expectations. As this collaboration also involves the client, the final product is completely optimized to their specifications.

Strict Quality Control and Testing: Our process hinges on quality. During casting and machining, we perform multiple quality checks to identify, and fix, potential problems. Every part we provide to you is reliable, durable and meets industry standards, the result of our thorough quality control.

Speed and Efficiency in Production: Our integrated process combining casting and CNC machining allows us to deliver prototypes and final products quickly, making it easier for clients to test and validate designs before full production. By streamlining production steps, we can reduce lead times and provide faster delivery to clients.

Conclusion

DUNTEK’s Castings is a CNC Machining service providing high-quality, complex metal parts with precise specifications in line with demands of industries. Through marrying CNC machining with the strengths of traditional casting, DUNTEK offers our clients the ability to realize their designs with reliability, efficiency, and customization.

Any questions or require a quote? Get in touch now!