What is a CNC machine? Today it’s time to explore CNC machining. You might have come across the term several times, especially when engineering professionals discuss various construction projects. Get ready to step into one of the most significant inventions in the contemporary manufacturing industry.

What is a CNC machine? Today it’s time to explore CNC machining. You might have come across the term several times, especially when engineering professionals discuss various construction projects. Get ready to step into one of the most significant inventions in the contemporary manufacturing industry.

The Basics: Decoding CNC

Let’s begin with the meaning of the acronym. CNC is in fact an acronym that refers to Computer Numerical Control. Sounds fancy, right? Well, it kind of is! In its simplest definition, CNC machining is the method of manufacturing where computer software is used to dictate how the factory tools and equipment should function.

Suppose you are using a controller in a game, and you are the avatar’s real-life counterpart on the screen. Now take that character and place it in the game world, and your input device or your controller is a software program. That is, in essence, what CNC machining is all about!

How Does It Work?

Here’s the process in a nutshell:

- Design: First, the design of the required part is developed in a three-dimensional virtual space by means of Computer-Aided Design (CAD).

- Programming: This basically means that the CAD model created is converted into a format understood by the CNC machine with the aid of Computer-Aided Manufacturing (CAM) software.

- Setup: We have to feed the raw material into the machine, and choose the right tools to be mounted into it.

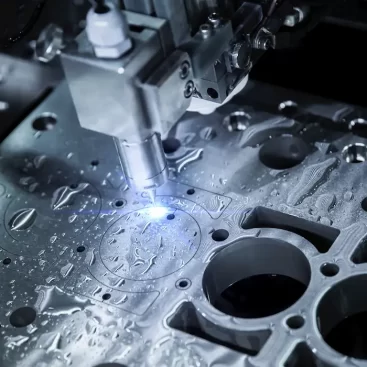

- Machining: Specific to shape a part, the CNC machine executes the programmed path, to cut all the required material.

- Finishing: After machining, other processes may be performed before the final product is complete.

The CNC Family: Make no mistake, a specific machine for specific job A

As stated above, CNC is not a single type of a machine. It’s like a big family, each member with its own special talent:It’s like a big family, each member with its own special talent:

- CNC Mills: It has characteristics similar to sculptors of the CNC world. They employ tools that that rotate in order to remove material from the work piece.

- CNC Lathes: This one is more like a vehicle in which metal is turned as in pottery wheel but this one is all about metal. When the material rotates the tools to give it a particular form.

- CNC Routers: These are a bit like mills, but they are the cabinitary; the woodworkers of the family. That is why they are perfect when it comes to dealing with softer material.

- CNC Plasma / Laser Cutters: These are the hot heads of the family as they are always ready to take up challenges. Specialized electrons know as plasma can cut through metal all the same as if it were a piece of butter with the help of super heat.

Why is CNC Machining Such a Big Affair?

- Precision: That is why CNC machines are compared to surgeons, who have steady hands. But they can work with such a high level of precision that even a human begin to think that his head is spinning.

- Consistency: The situation changes with a CNC machine as, once it has been programmed, it can produce a particular part every day, much less get bored with the task.

- Complexity: The creation of these parts can only be done by these machines and they are so delicate such that a watch maker would envy.

Efficiency: Machines, computers, does not need coffee break including the CNC machines. It means they can work on it 24/7, they can supply parts, they can produce parts. - Versatility: Some of the materials hard than steel and others as soft as butter can be machined by using CNC machines.

CNC Machining and 3D Printing

This gives one a cause to pause and think as to how CNC machining fits into the picture relating to 3D printing. Well, they’re like two peas in a pod:Well, they’re like two peas in a pod:

CNC is a process of shaping material beginning with a block and eliminating the necessary material to achieve the desired end product. It’s like sculpting.

3d printing that forms the part from a solid block or deposits the material layer by layer. It’s like stacking Legos.

Most of the factories that you will visit today will have both CNC machineries as well as 3D printers where one will be performing one specific task while the other does the same at the same time.

What is the Future of CNC Machining and what advancements can we expect to see in the Future?

Still, CNC machining is not something new, and it is rather exciting as it is still developing. We’re seeing some cool trends:We’re seeing some cool trends:

·Hybrid Machines: If you can visualize manufacturing tools that have a multifunctional capability such as cutting and printing combined in one tool then you are on the right track.

·AI Integration: CNC machines make three dimensional works smart than before.

·5-Axis Machining: This is followed by the ability to control functions yet again, to do things like adding another arm on the machine.

So there, now you know all about CNC machining – Thank you for reading! Ranging from the shape that CNC mill can achieve to the shapes that it can design this techinique is without doubt the wheel of modern manufacturing. The next time you examine a tightly milled fit in your car or in your smartphone, you can bet your bottom dollar that a CNC machine had a hand in creating it.

Are you having questions about cnc machining? Or perhaps, you have come across these machines at work? Ask DUNTEK – We’d really appreciate your feed back!